The Uhde process and design for ammonia plants is based on reliable and proven process steps. The main features are a top-fired primary reformer with a cold outlet manifold, a secondary reformer with a circumferential vortex burner and a magnetite-based three-bed radial heat exchange synthesis with one or two synthesis converters.

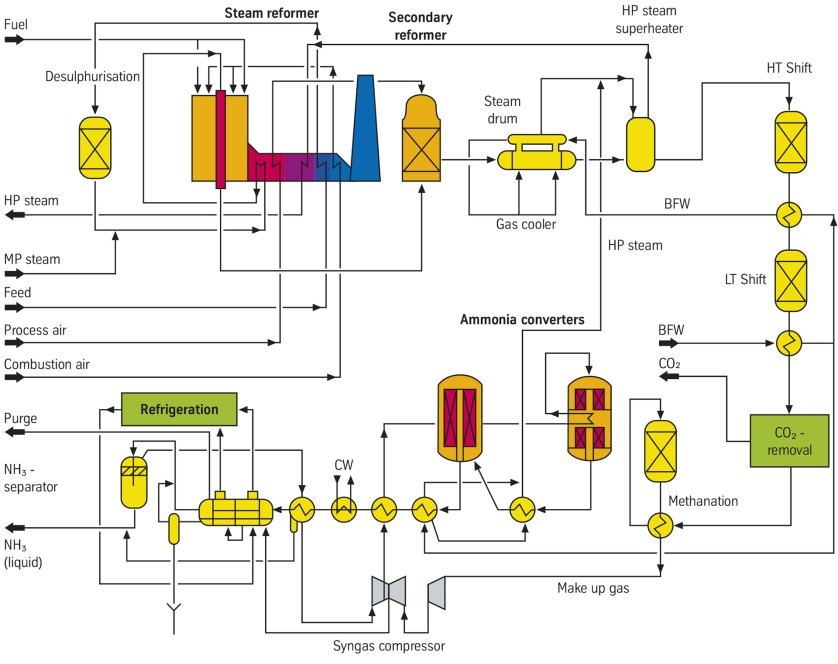

The feedstock (natural gas for example) is desulphurized, mixed with steam and converted to synthesis gas over nickel catalysts at approximately 40 bar and 800°C in the primary reformer. The Uhde steam reformer is a top-fired reformer which has tubes made of centrifugally-cast alloy steel and a proprietary cold outlet manifold system to enhance reliability.

Efficient, reliable, durable

The process gas leaving the primary reformer enters the secondary reformer, where process air is admitted to the syngas via a special nozzle system that provides a perfect mixture of air and gas. Subsequent high pressure steam generation and superheating permit maximum process heat exploitation to achieve optimized energy efficiency. Since its introduction in 1968, the Uhde secondary reformer has proved to be a reliable item of equipment with a long service life.

Emission reduction

Carbon monoxide is converted to carbon dioxide in the HT and LT shift over standard catalysts. Carbon dioxide is removed in a scrubbing unit, which normally uses the BASF-OASE or the UOP-Benfield process. Remaining carbon oxides are reconverted to methane by catalytic methanation at trace ppm levels.

The flowsheet diagram of an Uhde ammonia plant shows the conventional sequence of process steps that form the basis of most present-day ammonia processes. However, a more detailed scrutiny of the facts and figures shows that what appears to be a conventional set-up is in fact a most up-to-date ammonia plant concept. The total consumption figure (feed + fuel + electric power) per metric ton of ammonia produced is in the range of 6.6 to 7.2 Gcal (27.6 - 30.1 GJ), depending on local conditions (e.g. cooling water temperature) and project-specific requirements (such as the natural gas price, etc.).

The following process areas have undergone major modifications in order to achieve these figures:

- the steam reforming section including its waste heat recovery system;

- the CO2 removal unit;

- the ammonia synthesis unit.